Stock Control

Vendure includes features to help manage your stock levels, stock allocations and back orders. The basic purpose is to help you keep track of how many of a given ProductVariant you have available to sell.

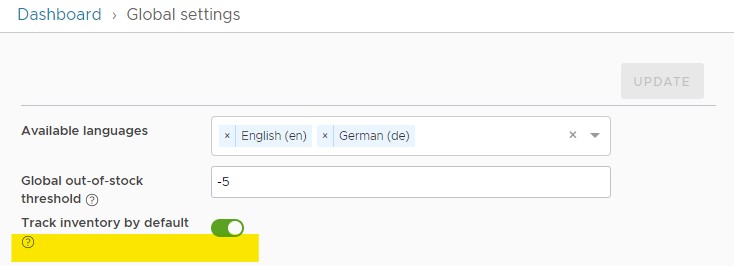

Stock control is enabled globally via the Global Settings:

It can be disabled if, for example, you manage your stock with a separate inventory management system and synchronize stock levels into Vendure automatically. The setting can also be overridden at the individual ProductVariant level.

Stock Control Concepts

- Stock on hand: This refers to the number of physical units of a particular variant which you have in stock right now. This can be zero or more, but not negative.

- Allocated: This refers to the number of units which have been assigned to Orders, but which have not yet been fulfilled.

- Out-of-stock threshold: This value determines the stock level at which the variant is considered “out of stock”. This value is set globally, but can be overridden for specific variants. It defaults to

0. - Saleable: This means the number of units that can be sold right now. The formula is:

saleable = stockOnHand - allocated - outOfStockThreshold

Here’s a table to better illustrate the relationship between these concepts:

| Stock on hand | Allocated | Out-of-stock threshold | Saleable |

|---|---|---|---|

| 10 | 0 | 0 | 10 |

| 10 | 0 | 3 | 7 |

| 10 | 5 | 0 | 5 |

| 10 | 5 | 3 | 2 |

| 10 | 10 | 0 | 0 |

| 10 | 10 | -5 | 5 |

The saleable value is what determines whether the customer is able to add a variant to an order. If there is 0 saleable stock, then any attempt to add to the order will result in an InsufficientStockError.

{

"data": {

"addItemToOrder": {

"errorCode": "INSUFFICIENT_STOCK_ERROR",

"message": "Only 105 items were added to the order due to insufficient stock",

"quantityAvailable": 105,

"order": {

"id": "2",

"totalQuantity": 106

}

}

}

}

Back orders

You may have noticed that the outOfStockThreshold value can be set to a negative number. This allows you to sell variants even when you don’t physically have them in stock. This is known as a “back order”.

Back orders can be really useful to allow orders to keep flowing even when stockOnHand temporarily drops to zero. For many businesses with predictable re-supply schedules they make a lot of sense.

Once a customer completes checkout, those variants in the order are marked as allocated. When a Fulfillment is created, those allocations are converted to Sales and the stockOnHand of each variant is adjusted. Fulfillments may only be created if there is sufficient stock on hand.

Configurable stock allocation

By default, stock is allocated when checkout completes, which means when the Order transitions to the 'PaymentAuthorized' or 'PaymentSettled' state. However, you may have special requirements which mean you wish to allocate stock earlier or later in the order process. With the new StockAllocationStrategy you can tailor allocation to your exact needs.